Ceramic Casting Sand Applications

Used in all types of foundry technique like coated sand, resin-bonded sand, sodium silicate sand, and clay-bonded sand.

As molding sand and core-making sand for iron casting, steel casting and alloy steel casting.

As a substitute for chromite sand for jacket core-making, oil duct core-making, tappet core-making of engine.

As facing sand for large steel castings.

As dry sand of sand box for EPC process and V method of casting processes.

Ceramic Casting Sand Physical and Chemical Properties

Item | Index | Item | Index(%) |

Bulk Density(g/ cm³) | 1.79-1.87 | Al2O3 | 65-82 |

Angle Factor | ≤1.1 | SiO2 | 15.32-21.6 |

Ambient Compressive Strength (Mpa) | 46 | Fe2O3 | 1.5-3.0 |

Refractoriness (℃) | ≥1800 | MgO | 0.23-0.7 |

Thermal Conductivity (W/m.K) | 0.5-0.6 | CaO | 0.16-1.5 |

Thermal Expansion Rate%(800-1450℃) | 0.50-0.65 | TiO2 | 1.99-2.71 |

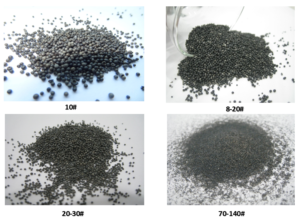

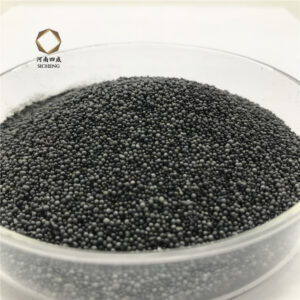

Ceramic Casting Sand Grain Size Composition and Grain Size Distribution

Grain Size Composition % | |||||||||||

mesh | 20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | AFS | |

μm | 830 | 550 | 380 | 270 | 212 | 150 | 109 | 75 | 53 | ||

Product Type. | 350# | 5-10 | 20-35 | 35-45 | 10-20 | 0-5 | 25-35 | ||||

450# | 0-10 | 25-45 | 25-45 | 10-25 | 0-5 | 35-45 | |||||

550# | 5-10 | 25-40 | 25-45 | 15-25 | 0-5 | 45-55 | |||||

650# | 10-25 | 20-40 | 20-40 | 15-25 | 5-8 | 60-70 | |||||

750# | 5-10 | 20-30 | 20-40 | 20-30 | 5-10 | 75-85 | |||||

950# | 5-10 | 20-40 | 25-40 | 10-20 | 0-5 | 90-100 | |||||

1000# | 0-5 | 25-40 | 25-40 | 15-25 | 5-10 | 100-110 | |||||