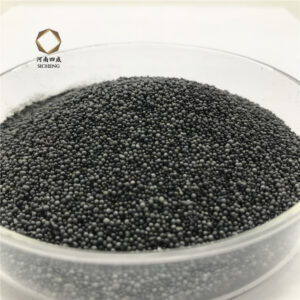

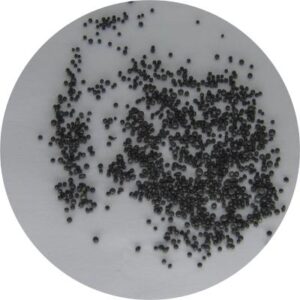

Ceramic foundry sand provides a unique combination of spherical shape grain, chemistry, and physical properties that result in numerous performance advantages compared with other foundry sands. Our ceramic foundry sand performs very well compared to chromite and zircon sands and has replaced these sands and silica sand in many foundry and casting applications. The grain surface is much smoother than other foundry sands, leading to better castings.

| Specification | Mesh | 14 | 18 | 26 | 36 | 50 | 70 | 100 | 140 | 200 | 281 | Pan | Particle Size Index | |

| μm | 1180 | 850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | Pan | AFS | GFN | |

| #25 | ≤2 | ≤10 | 30-50 | 30-50 | ≤5 | 20-30 | 30-50 | |||||||

| #30 | ≤2 | ≤10 | 20-40 | 40-60 | ≤20 | ≤5 | ≤2 | ≤0.5 | 27-35 | 40-60 | ||||

| #40 | 30-50 | 35-55 | ≤20 | ≤10 | ≤5 | ≤0.5 | 35-45 | 55-75 | ||||||

| #50 | 10-30 | 15-35 | 20-40 | ≤20 | ≤10 | ≤2 | ≤0.5 | 45-55 | 75-95 | |||||

| #60 | ≤10 | 10-30 | 25-45 | 15-35 | ≤20 | ≤5 | ≤0.5 | ≤0.2 | 55-65 | 95-115 | ||||

| #75 | ≤10 | 5-25 | 25-45 | 20-40 | ≤10 | ≤5 | ≤0.5 | 75-85 | 130-150 | |||||

| #90 | ≤10 | 30-50 | 20-40 | ≤15 | ≤3 | ≤2 | 85-95 | 160-180 | ||||||

| #100 | ≤3 | 10-25 | 40-60 | 10-20 | ≤10 | ≤3 | 105-115 | 190-210 | ||||||

| #125 | ≤2 | ≤20 | 45-65 | 20-40 | ≤20 | ≤8 | 125-135 | 225-245 | ||||||

| #150 | ≤2 | ≤20 | 45-65 | 20-40 | ≤10 | 150-160 | 260-280 | |||||||

| #180 | ≤1 | ≤10 | 45-65 | 30-50 | ≤20 | 180-190 | 300-320 | |||||||