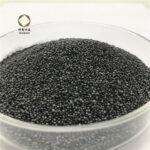

Ceramic Beads (Foundry Spherical Sand)

Ceramsite sand is high grade green casting material, made of high Alumina Calcined Bauxite, processed through fusing, spraying, sieving, get rid of impurity and special procedures. With ideal spherical shape, excellent fluidity and filling property, Ceramsite sand is widely used in various sizes of steel/iron/alloy casting parts. It is suitable for various bonds of casting mold