Fused ceramic sand, also called as ceramic Foundry Sand, is kind of man-made spherical shape ceramic particles featured by high refractoriness, low thermal expansion made by spraying melted from the fused bauxite. It provides a simple and efficient way in the foundry industry to improving the quality of the castings, reducing the production cost and avoiding environmental pollution so it is much better than silica sand. And it is also good substitution to Chromite sand and Zircon sand because of its lower price. At the present, Ceramic sand is acknowledged in the worldwide as the newest and the best ideal sand for the foundries and has a very wide feasibility of applications for the future development.

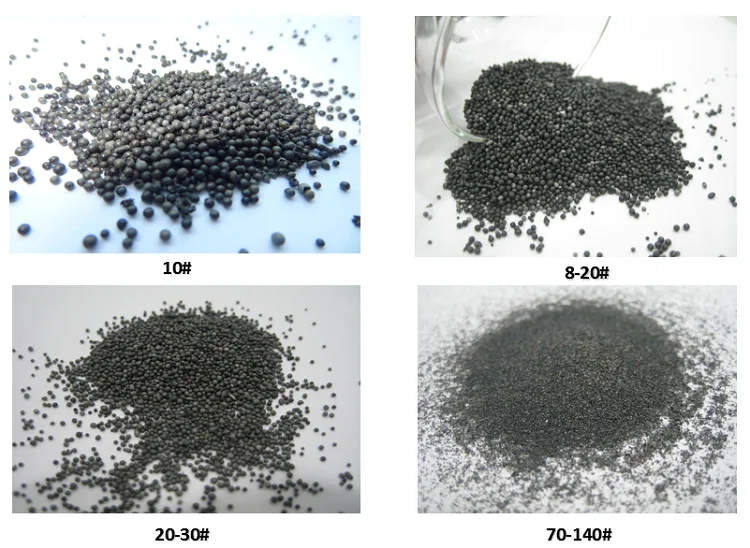

Grain type | ball, spherical |

Angularity | 1.1 max, similar to ball |

Bulk density | 1.95-2.05 g/cm3 |

Refractoriness | 1790℃ |

Thermal expansion | 0.13% (10 min at 1000 C ) |

Size | Available in all models, it can also be customized |

Content | |

Al2O3 | 70-75% |

SiO2 | 8-20% |

Fe2O3 | ≤ 3% |

TiO2 | ≤ 3.5 % |

CaO | ≤ 0.45 % |

MgO | ≤ 0.35 % |

K2O | ≤ 0.33% |

Na2O | ≤ 0.08 % |