1. Background: Why South African Chromite Ore?

South Africa holds some of the world’s highest-grade chromite deposits (Cr₂O₃ content often 44–48%).

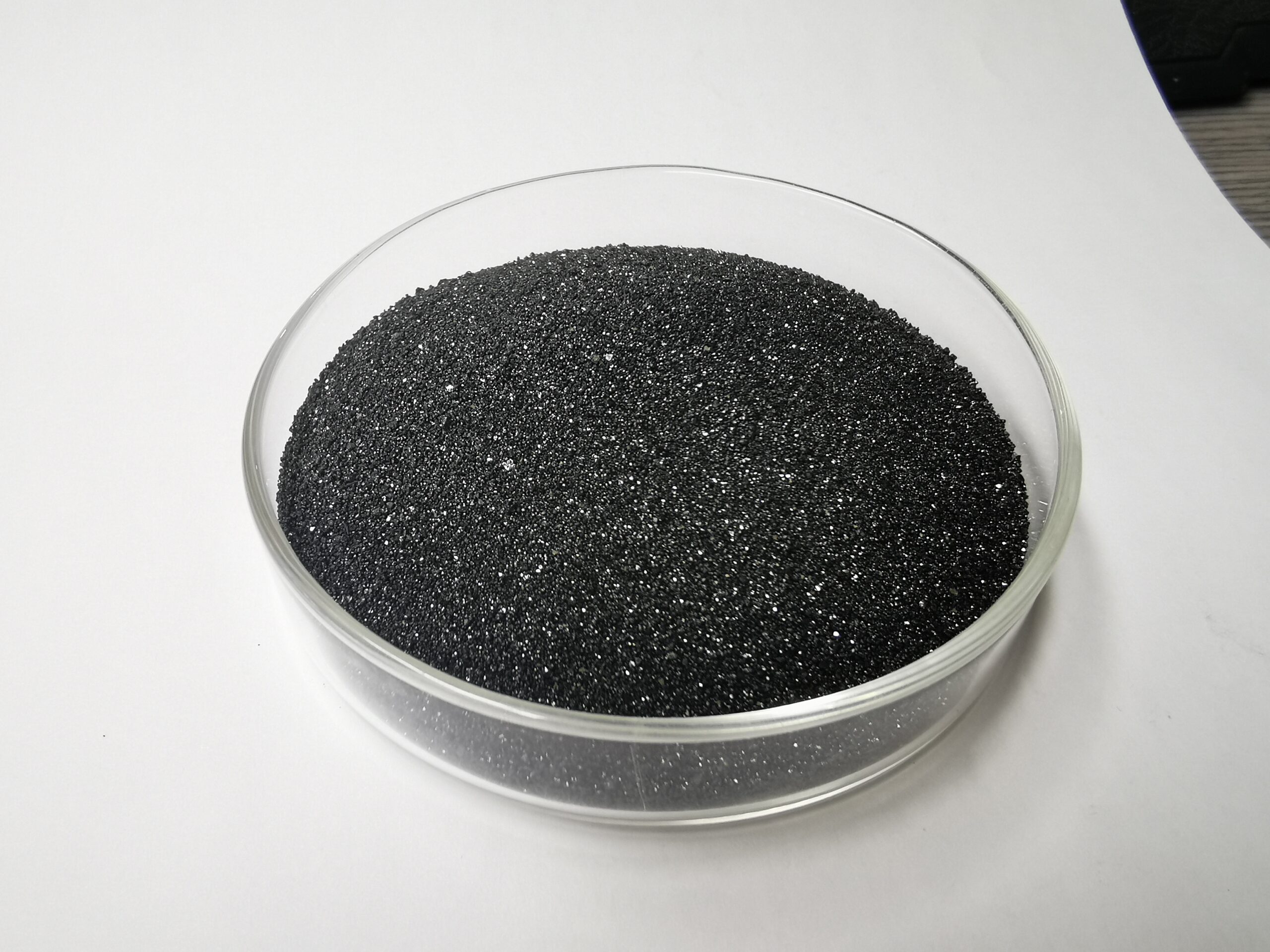

Chinese processors import South African ore, refine it, and produce premium-grade chromite sand (46% Cr₂O₃) for foundry applications.

This ensures better thermal stability, refractoriness, and lower SiO₂ content compared to lower-grade Chinese-mined chromite.

2. Key Features of China-Processed 46% Cr₂O3 Chromite Sand (South African Origin)

High Purity:

Cr₂O₃ ≥ 46% (ideal for steel/stainless steel casting).

Fe₂O₃ < 15%, SiO₂ < 1–3% (minimizes slag formation).

Superior Refractoriness:Melting point >1900°C, suitable for extreme casting conditions.

Low Thermal Expansion:Reduces veining and metal penetration defects.

Controlled Grain Size:AFS 45–65 (standard for molding and core-making).

3. Advantages of Buying from Chinese Processors

Cost Savings: Cheaper than direct imports from South Africa (due to lower labor/processing costs in China).

Stable Supply: China has established trade routes for South African chromite ore.

Custom Processing: Some Chinese suppliers offer washed, calcined, or blended chromite sand.

4. Applications

High-alloy steel & stainless steel castings (resists metal penetration).

Large industrial castings (e.g., pump housings, valve bodies).

Investment casting & precision molds (improves surface finish).

Foundry coatings (mixed with zircon or silica sand).