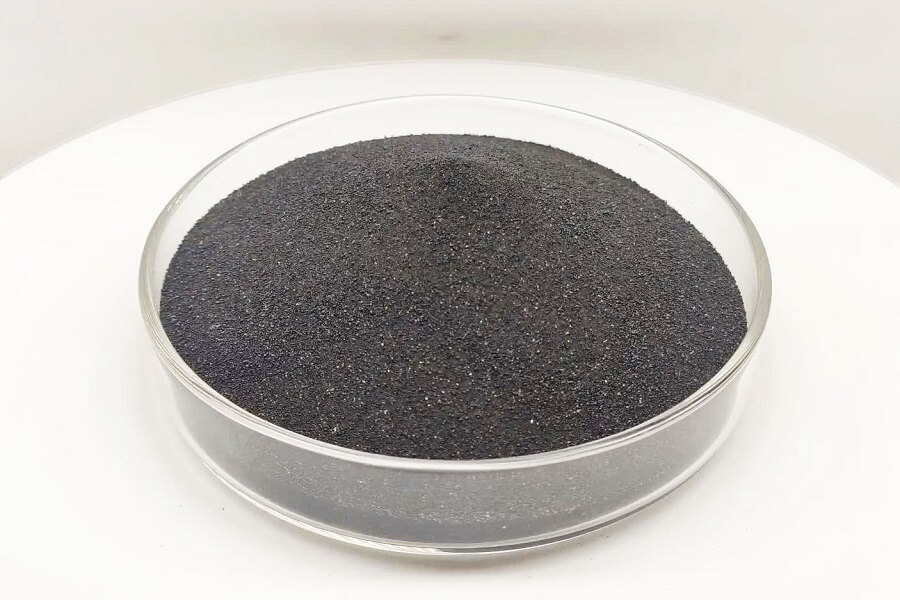

Coated Ceramic Sand for Foundry

Coated ceramic sand is a high-performance material used in the casting industry for making molds and cores. It represents a significant upgrade over traditional silica sand, especially for producing high-integrity, complex castings.

In simple terms, it is ceramic sand (the superior base material) coated with a thermosetting resin binder (the “glue”), specifically designed to be cured by heat.

1. What is the “Ceramic Sand” Base?

The core advantage lies in the base material, often known as Ceramic Beads or Spherical Ceramic Sand. It is not a natural sand but a man-made product, typically created by melting high-quality bauxite in an electric arc furnace and then spraying it to form small, spherical beads.

| Chemical Analysis[%] | |

| Al2O3 | 70-73 |

| SiO2 | 8-20 |

| Fe2O3 | ≤3 |

| TiO2 | ≤3.5 |

| CaO | ≤0.45 |

| MgO | ≤0.35 |

| K2O | ≤0.33 |

| Na2O | ≤0.08 |

| Physical Properties | |

| Grain shape | Spherical Ball |

| Roundness | 90% |

| Refractoriness: | >1790℃ |

| Shape Coefficient | ≤1.1 |

| Thermal Expansion Ratio | 0.13%(Heated up for 10 min at 1000℃) |

| Thermal expansion coefficient | 6×10-6 /℃(20-1000℃) |

| Thermal conductivity | 0.698W/M.K(1200℃) |

| Specific Gravity:: | 1.95-2.05g/cm3 |

| Bulk density(LPD): | 3.4 g/cm3 |

| Color: | Black |

| AVAILABLE SIZES | |

| AFS25-35,AFS35-45,AFS45-55,AFS55-65,AFS60-70,AFS70-80,AFS95-110 Customized sizes are available upon request | |

Key Properties of the Ceramic Sand Base:

Spherical Shape: Perfectly round particles offer excellent flowability, allowing them to fill complex mold patterns densely and evenly.

Low Thermal Expansion: This is its most critical property. Unlike silica sand, which expands significantly with heat, ceramic sand expands very little. This virtually eliminates casting defects like veining (cracks in the sand that get filled with metal).

High Refractoriness: It has a very high melting point (exceeding 1790°C), making it suitable for casting all metals, including steel and high-alloy irons.

High Strength & Durability: The sintered, dense beads are very strong and resist mechanical breakdown, allowing for excellent reclamation and reuse.

Chemically Inert: It is neutral (neither acidic nor basic), making it compatible with various binder systems.

2. The “Coated” Process: Creating the Coated Sand

The “coating” process is the same as for producing standard resin-coated sand, known as the hot-coating process:

Heating: The ceramic sand is heated to a specific temperature (around 140-160°C).

Mixing/Coating: The hot sand is mixed in a mixer. Thermosetting Phenolic Resin is added, which melts and coats the surface of each spherical sand particle.

Catalyst Addition: A hardening agent (usually Hexamine or “Urotropine”) is added to catalyze the resin’s curing when heated later.

Lubrication: Additives like Calcium Stearate are added to improve flowability and prevent caking during storage.

Cooling & Screening: The mixture is cooled and screened to obtain a free-flowing, ready-to-use product.

3. Key Advantages of Coated Ceramic Sand

By combining the superior base material with the resin coating, it offers outstanding benefits:

Elimination of Veining Defects: Due to its near-zero thermal expansion, cracks do not form in the core/mold, leading to a dramatic reduction in scrap rates for complex castings like engine blocks and cylinder heads.

Superior Casting Surface Finish: The spherical, smooth particles and low reactivity produce castings with very clean and smooth surfaces.

Excellent Flowability: Cores and molds can be packed more densely and uniformly, capturing fine details with high dimensional accuracy.

Reduced Resin Consumption: Because the spherical particles have less surface area and require less resin to bond effectively, usage can be 15-30% lower than with angular silica sand. This also lowers gas generation during pouring.

High Core Strength: The strong, durable sand particles and efficient resin coating result in very strong cores that can handle complex, thin sections.

Excellent Reclaimability: The ceramic beads are tough and can be recycled many times after the resin is thermally removed, improving long-term cost-effectiveness.

4. Common Applications

Automotive Industry: Engine blocks, cylinder heads, exhaust manifolds.

Hydraulic Components: Complex valve bodies and pump housings.

High-Alloy Steel Castings: Where resistance to burn-on and penetration is crucial.

Any complex core that is prone to veining or requires a high-quality surface finish.