Ceramsite sand is high grade green casting material, made of high Alumina Calcined Bauxite, processed through fusing, spraying, sieving, get rid of impurity and special procedures. With ideal spherical shape, excellent fluidity and filling property, Ceramsite sand is widely used in various sizes of steel/iron/alloy casting parts. It is suitable for various bonds of casting mold and can meet different needs of various customers.

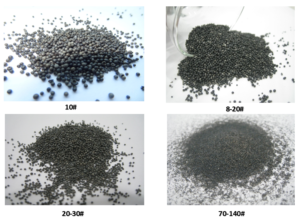

Specification (Size):

AFS20/AFS30/AFS40/AFS50/AFS55/AFS65/AFS75/AFS90/AFS100

Special grades can be customized.

Shape:Spherical Shape

Color:Grey black

Advantage:

Spherical Shape

As the shape is spherical with high density, ceramsite sand have excellent fluidity and filling character.

Glazed and Compact Surface

The surface of ceramsite sand is glazed and compact,it can be evenly covered by the bond such greatly reduce the resin consumption.

Excellent Refractoriness

With higher content of mullite phase than sintered sand, ceramsite sand is featured with high refractoriness.

Low Thermal Expansion

Very low thermal expansion ensures fewer or no casting defects.

Good regenerability

Each single bead has high strength and is not easily broken, the adhesive on its surface can easily fall off during regeneration. The ceramsite sand produced can be recycled many times and can basically be reused 8 to 10 times, greatly reducing casting costs.