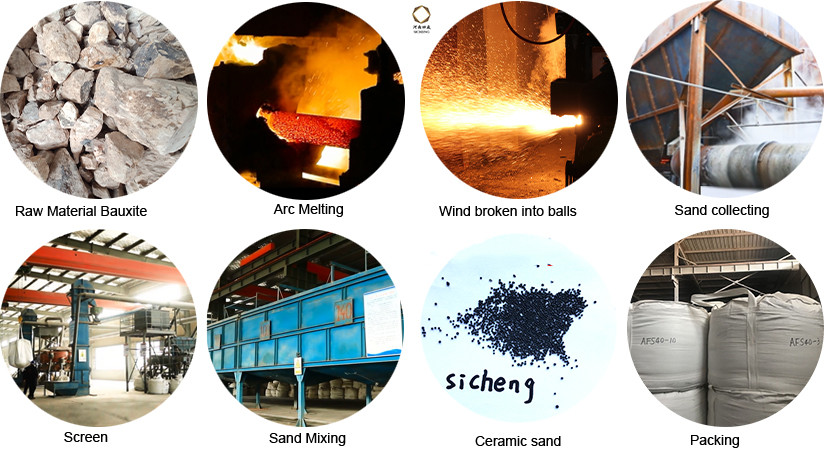

And it is also good substitution to Chromite sand and Zircon sand because of its lower price. At the present, Ceramic sand is acknowledged in the worldwide as the newest and the best ideal sand for the foundries and has a very wide feasibility of applications for the future development.

Ceramsite sand Physical and Chemical Composition

| Chemical Analysis[%] | |

| Al2O3 | 70-75 |

| SiO2 | 8-20 |

| Fe2O3 | ≤3 |

| TiO2 | ≤3.5 |

| CaO | ≤0.45 |

| MgO | ≤0.35 |

| K2O | ≤0.33 |

| Na2O | ≤0.08 |

| Physical Properties | |

| Grain shape | Spherical Ball |

| Roundness | 90% |

| Refractoriness: | >1790℃ |

| Shape Coefficient | ≤1.1 |

| Thermal Expansion Ratio | 0.13%(Heated up for 10 min at 1000℃) |

| Thermal expansion coefficient | 6×10-6 /℃(20-1000℃) |

| Thermal conductivity | 0.698W/M.K(1200℃) |

| Specific Gravity:: | 1.95-2.05g/cm3 |

| Bulk density(LPD): | 3.4 g/cm3 |

| Color: | Black |

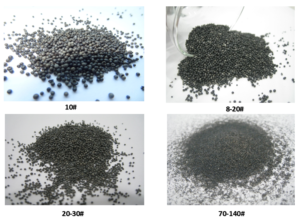

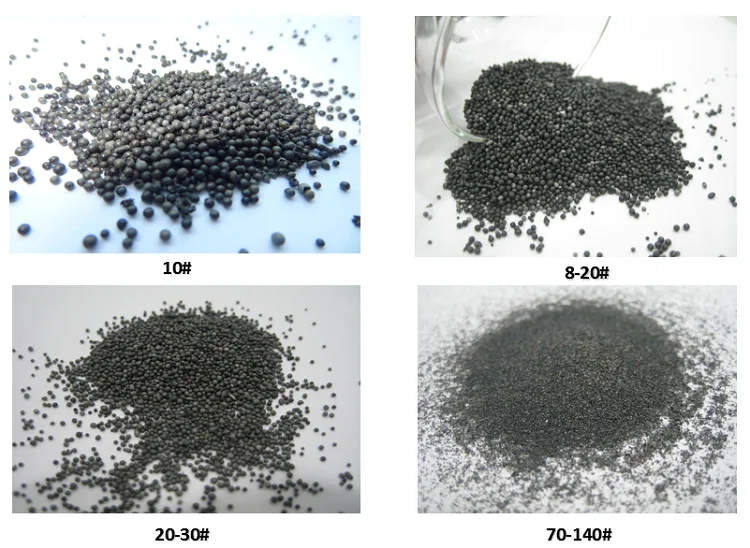

| AVAILABLE SIZES | |

| AFS25-35,AFS35-45,AFS45-55,AFS55-65,AFS60-70,AFS70-80,AFS95-110 Customized sizes are available upon request | |

| Applications | Grit Size | AFS SIZE |

| Foundry sand for Lost foam | 8-15#(10#)10-20#,20-30# | AFS25-35 |

| Filler sand | 30# | |

| No bake sand including furan resin /alkaline-phenolic resin molding and core making/ Pep set /Sodium-silicate bonded sand | 30-50#,40-70#,50-70#,70-140# | AFS35-45,AFS25-35,AFS45-55, AFS55-65,AFS60-70,AFS70-80 |

| Shell molding, resin coated sand casting | 50-100#,70-140#,100-200# | AFS55-65,AFS60-70,AFS70-80, AFS95-110 |

| Lost foam casting coating | 140-270#,-200# | |

| Molding sand alcohol-based coating | -200# | |

| 3D printing, precision casting, investment casting | -140# |

| Sieve | 10 | 20 | 30 | 40 | 50 | 70 | 100 | 140 | 200 | 270 | pan | AFS |

| size | 1700 | 850 | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | pan | |

| 20-40 | 15-40 | 30-55 | 15-35 | ≤3 | 15-25 | |||||||

| 30-50 | ≤10 | 25-45 | 35-55 | 5-15 | ≤5 | ≤2 | 25-29 | |||||

| 40-70 | ≤10 | 25-45 | 20-40 | 5-25 | ≤7 | ≤5 | 35-39 | |||||

| 40-100 | ≤3 | 10-25 | 25-40 | 25-45 | 10-25 | ≤10 | ≤5 | 45-55 | ||||

| 50-100 | ≤10 | 10-30 | 30-50 | 15-35 | ≤15 | ≤5 | ≤2 | ≤1 | 55-65 | |||

| 50-140 | ≤8 | 10-25 | 20-45 | 20-45 | 5-20 | ≤7 | ≤2 | ≤1 | 60-70 | |||

| 70-140 | ≤10 | 10-25 | 25-45 | 15-35 | ≤15 | ≤5 | ≤2 | 75-85 | ||||

| 100-200 | ≤3 | 10-35 | 35-55 | 15-35 | ≤10 | ≤5 | 95-115 | |||||

| 140-270 | ≤5 | 5-25 | 40-60 | 25-40 | ≤15 | 155-175 | ||||||

| 6-20 | for lost foam | |||||||||||